We’re dedicated to manufacturing top-notch washi tapes that will bring your brand to greater heights.

Our dedicated quality control team pulls no stops in making sure your washi tapes are of the highest quality, from raw material selection to final inspections. All washi tapes are carefully inspected to meet established global standards perfectly. We can also provide third-party quality inspections based on your demands.

All raw materials used for our premium washi tapes are guaranteed eco-friendly and sourced from certified material suppliers with years of industry know-how. Our quality control specialists go through the procured materials, inspecting the paper thickness, paper coating, and color attachment before using them on our custom washi tapes.

To guarantee the quality of our premium washi tapes, they go through several tests that are calibrated to global standards.

Through a paper thickness gauge, our inspectors measure the thickness of washi paper to the required industry standards and utilize composition analysis instruments to check the coating and gluing of the washi paper.

The bottom of the tape is attached to corresponding weights and the timer starts to measure the stick time. The lasting adhesive property is obtained by measuring the displacement of washi tapes on the vertical test plate and the time to failure at specific loads

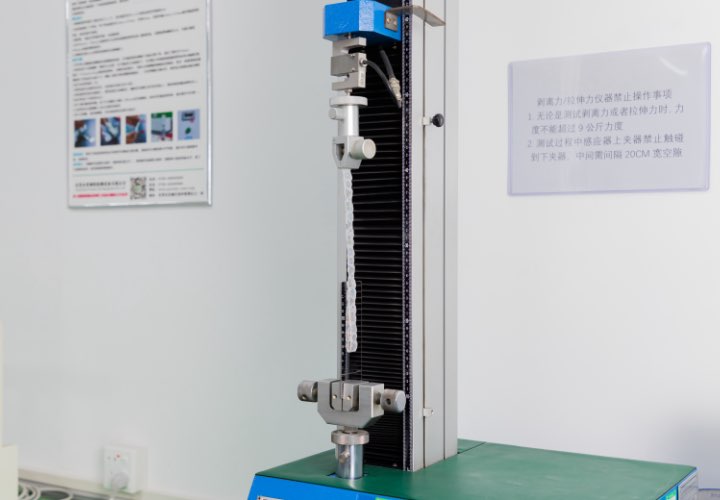

To judge whether the adhesive performance of adhesive tape is qualified and meets the requirements of use, peel strength is one of the most important indicators. The washi tape is tightly stuck to a clean steel plate and then tested by a peel force tester to measure the average peel force of the tape.

The tape is stuck to a clean test stand and it is placed in a temperature-set oven to see at what temperature the tape will lose its adhesion.

Our inspectors conduct printing adhesion tests by selecting a variety of colors for printing and observe the degree of uniformity and accuracy of color adhesion under a magnifying glass.

Foil adhesion testing is conducted to test the lastingness of the foil and coating. Inspectors repeatedly use high-adhesive tape to stick the foil on the washi paper to check whether the foil will flake off.

Finished custom washi tapes go through a comprehensive final inspection process before being packaged and shipped. The final inspection includes color examination, dimension calibration, and image sharpness. Tapes that don’t meet our high-quality benchmarks are taken out of the pool, ensuring you only get the best from us.

Momo Washi meets international standards when it comes to manufacturing premium washi tapes.

We are commited to develop amazing washi tape designs and new crafts to enlighten your brand.

Copyright © 2021, Momo Washi. All rights reserved. Powered by MML