Custom Washi Tape

Leading Manufacturer

Since 2011, Momo Washi has established itself as the leading washi tape manufacturer, offering an extensive range of high-quality washi tapes. We provide exceptional support to small and large businesses through our superior customization service, design capabilities, and fast-paced production.

Capabilities in Figures & Our Partners

CHANEL

Starbucks

Mercedes-Benz

Our Washi Tape Categories

Momo Washi provides a full line of well-designed washi tapes, including printed washi tape, die cut washi tape, glitter washi tape, foil washi tape, stamp washi tape, printed clear tape, and foil clear tape.

Quality Washi Tapes Help You Stand Out

The craftsmanship we use to make our washi tapes gave it several marketable qualities that help you bring in your target audience.

Repositionable

Can be easily peeled off and re-stuck to various surfaces.

Writable

Choose materials and finishes to customize writable tapes.

Eco-Friendly

Made out of renewable and biodegradable materials.

Easy to Tear

The material makes it easy for anyone to tear them by hand.

High Toughness

With high tensile strength, they have optimized durability.

Traceless Sticky

When removed, do not leave any sticky residue.

Excellent Packaging Makes us Stand out

Create a powerful first impression through our custom packaging service for your washi tapes, allowing you to boost your brand awareness in your target market.

Plastic Tube

Paper Box with Window

OPP Bag

Head Tag Box

Head Card Packaging

Head Card Packaging

Drawer Box

Ball Packaging

Momo Washi Gives You

Free Samples & Fast Prototyping

Receive your free washi tape samples within 7 days from consultation.

Short Lead Time

Streamlined production allows us to complete orders within 15 days.

Low MOQ

Whether you need 50 or 600 custom washi rolls, we can supply the right amount you need.

Strong Manufacturing

15 years of production expertise and scientific process management ensure a streamlined production.

Get in Touch with Us

Full Customization to Fit Your Business

Momo Washi offers fully customizable washi tapes with extensive made-to-order options to meet your budget and business requirements.

Your Personalized Designs

Browse our design resources where we display our past washi tapes designs. You can also explore our website to get inspiration for the custom washi tapes you want. With our professional designer’s help, we can adjust our design to create a unique concept for your business.

Helpful Design Resources

Browse our design resources where we display our past washi tapes designs. You can also explore our website to get inspiration for the custom washi tapes you want. With our professional designer’s help, we can adjust our design to create a unique concept for your business.

Multiple Customization Options

Cutting

Through assorted cutting techniques, we offer die cut washi tapes, hollow pattern washi tapes, stamp washi tapes, and overlap washi tapes.

Material

From washi paper, PET, PVC to foil and laser Film, we provide various options of materials of the washi tape to satisfy your requirements.

Pattern

You can choose our design templates, or provide your drawings in the file format of AI, PSD, JPG, and PDF. Rest assured that we protect your patterns’ copyright.

Paper Thickness

Choose the appropriate paper thickness from 0.07 mm to 0.09 mm, according to your desired craftsmanship

Paper Core

Our paper cores are available in a variety of sizes and types. Our paper cores can be customized in diameters of 25mm, 32mm, 38mm and 76mm, of which 32mm is the most conventional size. We offer different types of paper core such as blank core, logo printed core, kraft paper core, and plastic core to fit your packaging needs.

Printing

CMYK Printing

The four-color CMYK printing equipment is suitable for multi-colored graphics to create economical washi tapes with vibrant design.

Digital Printing

If you have high requirements on color reproduction with a higher budget, digital printing is suitable for you to achieve high-grade prints

Pantone Printing

Pantone printing is ideal for precise color matching for branding and logos and suitable for top-end washi tapes. You are supposed to provide the PMS number.

Length & Width

We can customize the roll widths and lengths to achieve your business goals.

The length of our washi tapes can be set from 1m to 100m while the width can range from 3mm to 294mm.

Length

Width

Finishing

Momo Washi offers a combination of different finishes and looks for new ideas and inspirations on appearance and texture.

Printed

Matte effect

Foil

mutiple colors for your choice

Glitter

Sparkling and frosted effect

Mixed Effect

Printed & foil, foil & glitter, printed & foil & glitter

Special Effect

UV Spot, glitter powder

New Crafts

Scodix raised foil effect & holographic effect

Reliable Manufacturing Processes

Scientific production management and lean manufacturing process ensure a streamlined production of premium washi tapes.

- Printing >>

- Foil Printing >>

- Varnishing >>

- Die Cutting >>

- Rewinding >>

- Slitting >>

- Final Inspections >>

- Packaging >>

Printing

Utilizing advanced CMYK, digital or Pantone printing machines to efficiently complete the printing of the patterns in high precision and color accuracy.

Foil Printing

The bronzing patterns are created on the washi tape by hot stamping and cold stamping machines.

Varnishing

Adding a layer of varnish or matte oil on the surface of the washi tape to protect the printed patterns and make them look glossy and upscale.

Die Cutting

Washi paper is cut into various shapes precisely and efficiently by die-cutting machines.

Rewinding

After printing, varnishing, and cutting, washi paper will be rolled up in a specific length, which is convenient for the following slitting.

Slitting

Each roll of printed tapes will be slitting into a smaller roll in customized width.

Final Inspections

All the finished tapes are 100% inspected for compliance with your specifications and requirements before they’re packed up.

Packaging

After final inspections, all the finished washi tapes will be packed into different customized packages to be shipped.

Highly Equipped Workshops&Advanced Machines

Printing Workshop

Quality Inspection Workshop

Cold Stamping Workshop

Die Cutting Workshop

Rewinding Workshop

Slitting Workshop

Packaging Workshop

Rigorous Testing to Ensure Excellent Quality

To guarantee the quality of our premium washi tapes, they go through several tests that are calibrated to global standards.

- Paper Thicknesss Test >>

- Lasting Adhesive Test >>

- Peel Strength Test >>

- Temperature Resistance Test >>

- Ink Adhesion Test >>

- Foil Adhesion Test >>

- Raw Materials Inspections >>

- Final Product Inspection >>

Paper Thickness Test

Through a paper thickness gauge, our inspectors measure the thickness of washi paper to the required industry standards and utilize composition analysis instruments to check the coating and gluing of the washi paper.

Lasting Adhesive Test

The bottom of the tape is attached to corresponding weights and the timer starts to measure the stick time. The lasting adhesive property is obtained by measuring the displacement of washi tapes on the vertical test plate and the time to failure at specific loads

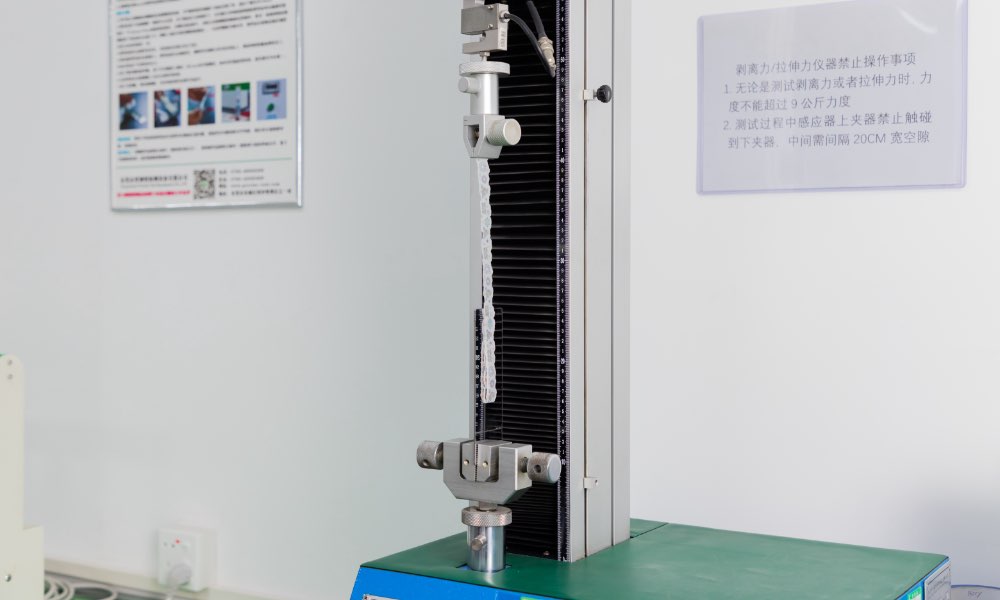

Peel Strength Test

To judge whether the adhesive performance of adhesive tape is qualified and meets the requirements of use, peel strength is one of the most important indicators. The washi tape is tightly stuck to a clean steel plate and then tested by a peel force tester to measure the average peel force of the tape.

Temperature Resistance Test

The tape is stuck to a clean test stand and it is placed in a temperature-set oven to see at what temperature the tape will lose its adhesion.

Ink Adhesion Test

Our inspectors conduct printing adhesion tests by selecting a variety of colors for printing and observe the degree of uniformity and accuracy of color adhesion under a magnifying glass.

Foil Adhesion Test

Foil adhesion testing is conducted to test the lastingness of the foil and coating. Inspectors repeatedly use high-adhesive tape to stick the foil on the washi paper to check whether the foil will flake off.

Reliable Raw Materials & Comprehensive Inspections

All raw materials used for our premium washi tapes are guaranteed eco-friendly and sourced from certified material suppliers with years of industry know-how. Our quality control specialists go through the procured materials, inspecting the paper thickness, paper coating, and color attachment before using them on our custom washi tapes.

Stringent Final Product Inspection

Finished custom washi tapes go through a comprehensive final inspection process before being packaged and shipped. The final inspection includes color examination, dimension calibration, and image sharpness. Tapes that don’t meet our high-quality benchmarks are taken out of the pool, ensuring you only get the best from us.

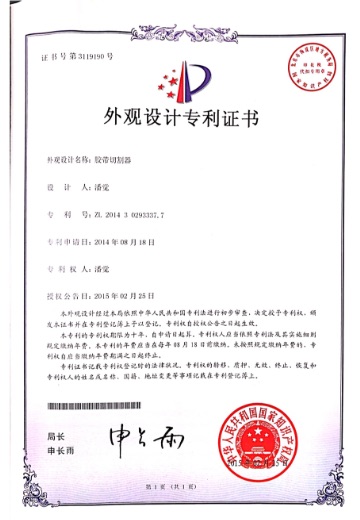

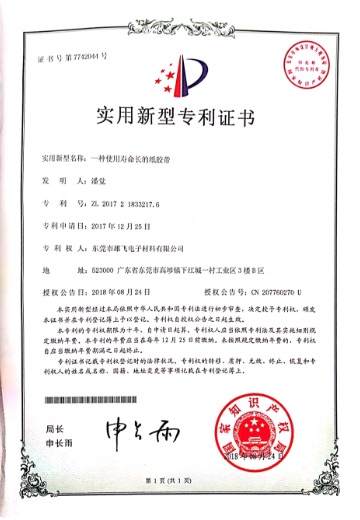

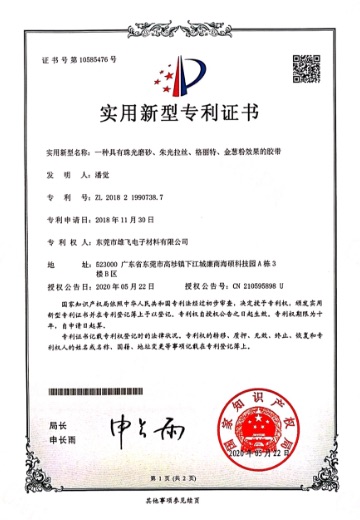

Certifications Show Our Attitude

Momo Washi meets international standards when it comes to manufacturing premium washi tapes.

Patents of Craftsmanship

We’ve constantly secured patents for our processing designs and techniques with our drive to deliver better and more reliable washi tapes.

Our Footprints on the Way to Washi Tape

Founded in 2009, Momo Washi began producing washi tapes and stickers, utilizing CMYK printing machines and cutting machines to produce CMYK printed products.

In expanding the range of Washi tapes and stickers crafts to meet market growth, we added new crafts like printed puzzles, memo pads, and postcards.

Engaging in fully independent production, we acquired complete production lines for various products, along with making OEM & ODM services available.

Amidst the COVID-19 pandemic, we helped customers in various countries start their businesses. We also met increasing demand, optimizing our productivity by expanding our production lines.

We are continuing forward…

Our Mission

To cultivate a greater appreciation for washi tapes, we develop creative craftsmanship that diversity our product range. In meeting this goal, we streamline manufacturing processes to provide matchless quality products and one-stop-shop services. Every effort to ease your concerns helps in boosting your brand’s reputation in the market.

Our Sustainable Industrial Practices

A key part of our corporate culture is the focus on sustainability to protect the environment and help you ensure your customers’ safety. In an effort to reduce pollution, we use eco-friendly materials, such as biodegradable, reusable washi paper, adhesive, and ink that are free of any harmful substances and tested for their safety to use.

Customized Exquisite Washi Tapes With Momo Washi!

We are commited to develop amazing washi tape designs and new crafts to enlighten your brand.

Copyright © 2021, Momo Washi. All rights reserved. Powered by MML